Its about time…..that I post another update you might say….but I have been busy experimenting again with my 3D printer to produce a prototype engine pylon. I’ve managed to create a 3D model, but struggling to get a successful print. I’ve had much success with printing the jet engine fans, so am a bit perplexed as to why I’m having trouble again.

Anyway, I have made the engine pylons out of wood in the true spirit of my AeroArt and the engines themselves. As this model is for myself, I don’t mind experimenting with a few 3D printed short-cuts…🤓. You may question that my previous posts show the engines and pylons already made, this is true, but I used them on the FedEx 747F to save some time.

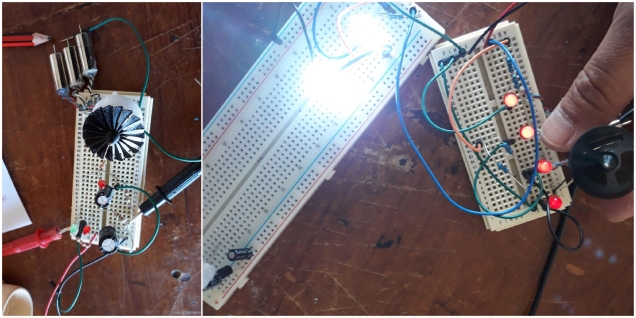

Ive also made the wingbox and carved out tracks to run the wiring for the lights and engines, as well as hole bored for the cockpit lights. Speaking of which my buddy has been busy working on the electronics to support the lights and engine micro-motors…yes, this model will have Jet fans that will spin… The wingbox will house all the electronics, and will be accessible by removing the wings/wingbox which is a single unit. I just need to blend in the wings and wing fairings into the wingbox. To do this I’m also experimenting using a flexible gap filler that can be hand shaped and painted.

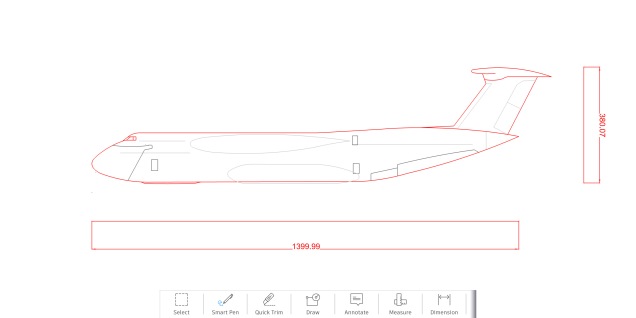

On another note, my FedEx customer has commissioned and challenged me to build another model, but this time in a larger scale – 1:50 scale. The aircraft is the mighty C5A Galaxy. So this model will be about 1.4 metres long, the largest I have built to date. The first step for myself in this challenge is creating drawings and patterns, so stay tuned for another big project on all scales…

Good job lad. Great update. Keep us all posted. Yay. 👍💯

LikeLiked by 1 person